SolutionsWhat Are Specialty and Reactive Adhesives?

For diverse application needs, APPLIED Adhesives offers a variety of specialty adhesives that can help you operate efficiently, reliably, and with lower costs. Often used for specialty applications, advanced reactive adhesives use chemical reactions to create a bond. APPLIED Adhesives’ innovative technologies include: web, cyanoacrylates, methyl methacrylate, epoxies, urethanes, and silicones.

A type of hot-melt specialty adhesive, web adhesive is delivered as a nonwoven, web-like material that handles similar to fabric.

Cyanoacrylates (CA) are a family of strong, fast-acting reactive adhesives that can bond quickly to a range of metallic, plastic, and rubber substrates at room temperature. CA single-component liquid adhesive is sometimes known as “instant glue” or “superglue.”

Reactive Methyl Methacrylate Adhesives (MMA) belong to a family of high-performance thermoplastics that bond metals, plastics, and composites. Compared to epoxies and CAs, MMA is more flexible. MMA is an aggressive two-component structural adhesive that has strong optical clarity, abrasion resistance, and physical strength.

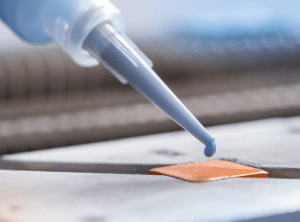

Epoxy adhesives are versatile, thermosetting polymers, which can be used for adhesive, sealant, potting/encapsulation, impregnation, and coating. They are often used for structural adhesive applications and for electrical insulation. Two-component epoxies cure at room temperature and one-component epoxies cure with heat. Some of the key benefits of using reactive epoxies include: physical strength, resistance to chemical and environmental damage, and dimensional stability.

When cured, one- or two-component urethane adhesives can be rigid or flexible. Urethanes bond well to a variety of substrates. They are often used in the automotive, marine, and wood industries.

Specialty silicone adhesives are designed to resist weather, water, and chemicals. One- and two-component silicone compounds are available—with elastomeric adhesives and sealants being the most widely used. These polymeric materials contain the SI-O chemical group in their structure, which results in a gel-like consistency. Silicones can be used, and remain highly elastic, in environments with a continuous temperature range of -100°F (-75°C) to 390°F (200°C). For short periods, silicones also work up to 575°F (300°C).

GorillaPro products can help repair and improve the reliability of almost any piece of equipment or machinery. With the full complement of maintenance adhesives, repair epoxies, lubricants, and sealants you can help prevent unplanned maintenance and costly downtime. Keep your machines running at top performance with GorillaPro products. They are Brute Strength. Professional Grade.™