How To Prevent Char Buildup in Your Hot Melt System

To put it bluntly: Adhesive char is not something you want inside your hot melt system.

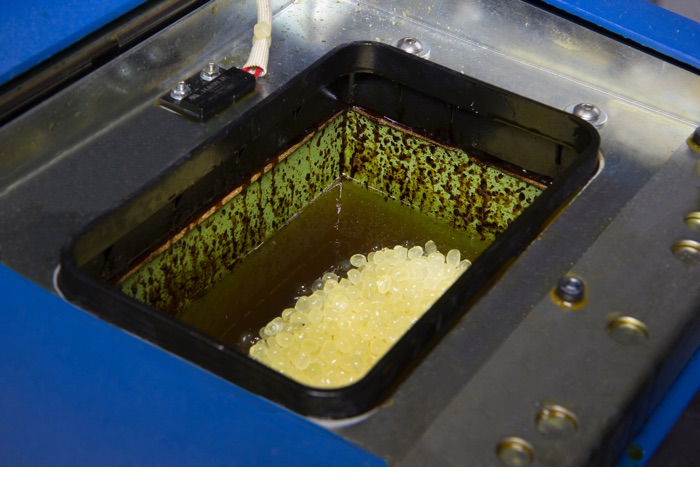

Adhesive char is the residue that results from hot melt adhesive. As it inevitably builds up over time, it creates the possibility for clogs, especially as char breaks away from the tank or hose walls and flows through the system. If no action is taken, quality and production can suffer, not to mention downtime due to clogs.

The time it takes for char to build will vary, depending on the tank life of specific hot melt glue types. However, there are ways to reduce the likelihood that charring will occur. Use of high-quality adhesive will help to reduce char build up.

As hot melt experts, we want to help you extend equipment life, minimize downtime, and maintain seal quality with these proven maintenance tips.

Tip #1: Keep the adhesive and the hot melt system free of debris.

When any debris gets into the adhesive and moves through the system, it adheres to the tank and hose walls. If you don’t catch the charring quickly, it can create a major issue, creating blockages in the hoses, guns, manifold, etc.

Adding an Auto-Feeder is a great way to reduce debris getting into the system. Otherwise, keep the adhesive boxes/bins closed and protected from debris. Never sweep up adhesive and put it into the system or back into the adhesive box/bin. Additionally, always keep the tank lid closed.

Tip #2: Schedule routine preventive maintenance.

There’s more to keeping a hot melt system clean and free of debris than just wiping down the outside. It’s extremely important to clean the inside as well. Flushing the unit regularly ensures that debris doesn’t accumulate in the system. Contact APPLIED for information on flushing procedures or simply have us visit your plant for preventive maintenance on your equipment.

Check and replace tank filters on a regular basis

This can help improve the way the system functions and reduce the likelihood of charring. You should also include hoses and guns in the maintenance schedule. Check the hoses, nozzles, and fittings for damage, and replace them as soon as possible.

For this type of maintenance, we recommend that the system be completely flushed. When to flush depends on your hours of operation. For example: If you’re operating with three, eight-hour shifts, you should consider flushing your system every six to eight weeks, or sooner if you notice char forming or a dark/burned adhesive color.

Tip #3: Use a setback/standby.

Most hot melt systems employ a setback/standby feature. Temperature control setback/standby allows the adhesive unit to cool to a predetermined temperature when not actively in use. Generally used when the operators are at lunch or break, this helps preserve the adhesive in the tank and lessens the possibility that it will degrade and char. Additionally, it heats to setpoint quicker than shutting down the system.

Tip #4: Don’t exceed the recommended temperatures.

It’s a common belief that increasing the temperature will cause the adhesive to melt more quickly. While this is basically true, it can decrease the life of the adhesive as well as the life of the system.

Heating the system temperatures above what the manufacturer recommends also increases the chance of char which can cause major productivity problems. Using the lowest possible temperature that still keeps up with demand will reduce the amount of char build up. Always check the data sheet of the adhesive for the proper operational temperatures.

Get Support From Hot Melt Experts

Following these tips can help you to increase the life of your hot melt systems, especially if you follow preventative maintenance program. When clean and free of char, you may even see an increase in productivity and won’t have to address production shutdowns due to poor quality seals or clogs in the machine.

You may also need to reach out and get support. APPLIED is here for any adhesive equipment, parts, and troubleshooting needs. We offer compatible parts, lab testing, and technical support for companies to increase performance. Contact us today if you’re experiencing char buildup.