Customized, Adhesive Solutions for Optimal End-of-Line Packaging Operations

If you’re tired of unplanned downtime due to end-of-line bottlenecks, why not try a different approach?

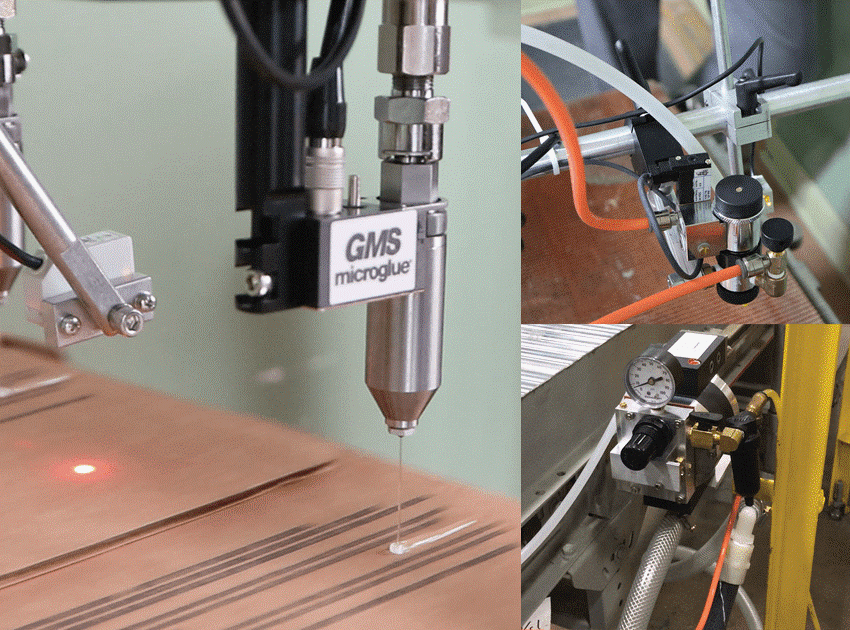

APPLIED Adhesives provides tailored end-of-line (EOL) packaging solutions including adhesives, equipment, parts and service designed to streamline your packaging process, reduce downtime and increase throughput. Our advanced, high quality equipment, coupled with our extensive Metallocene, EVA and Hybrid adhesive knowledge, ensures that your packaging line operates at peak performance, enabling you to meet production targets with ease. With 25+ warehouses across North America, we have you covered.