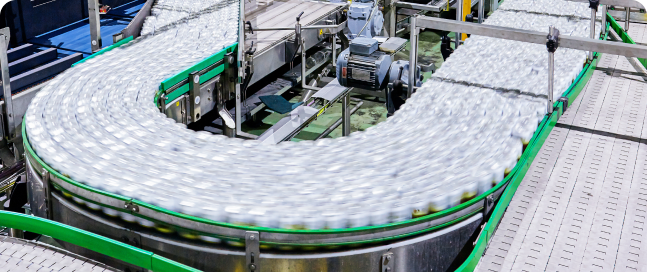

A premier beverage co-packer located in Pennsylvania known for servicing high-profile partners packages more than 20 million cases of beverages each year. Their facilities handle packaging for glass and aluminum can configurations and kegs. Because they specialize in high-volume production for multiple, iconic brand owners, seamless operations and reliable packaging integrity are required to meet their partners’ exacting standards.

Client Success Case Study

Optimizing Adhesive Performance for a Leading Beverage Co-Packer

The Customer

Case Study: Packaging Performance Restored

When failing adhesive solutions disrupted packaging quality and consistency, this co-packer needed more than a supplier: they needed a true partner. This case study shows how APPLIED Adhesives stepped in with the right products, equipment upgrades, and hands-on support to keep production running smoothly and reliably.

- The Obstacles

- The APPLIED Approach

- The Bottom Line

The Obstacles

The co-packer faced ongoing adhesive performance issues that disrupted their case wrap process, leading to compromised packaging quality. Specifically, the incumbent supplier’s low-temperature adhesive was failing under operational conditions, causing wrap-around failures on cases. Compounding the problem, the supplier lacked technical support to address these challenges, leaving their maintenance team without the resources to resolve the issue.

Equipment limitations added further strain. The plant’s adhesive dispensing systems, including aging Nordson Pro-Blue 15 units, required upgrades to align with modern performance standards. Despite the operational urgency, the plant team struggled to implement changes effectively, further held up by inconsistent maintenance follow-up and insufficient technical guidance.

The APPLIED Approach

APPLIED Adhesives took a strategic, hands-on approach. Our field technician identified the need for a high-temperature adhesive to replace the underperforming product. After a successful trial, the switch immediately eliminated the case wrap issues.

Recognizing additional opportunities to optimize operations, APPLIED supported the co-packer in transitioning from Nordson equipment to Graco InvisiPac systems, enhancing adhesive application consistency and reducing maintenance requirements. The facility reallocated an InvisiPac unit from another plant, and APPLIED’s factory-trained field technicians performed a complete system teardown, rebuild and calibration, including $50,000 in critical parts.

Our team remained on-site, troubleshooting and resolving all issues until the line was fully operational. APPLIED also established a cadence of business reviews with the customer, presenting a service agreement that was ultimately accepted, laying the groundwork for ongoing process improvements.

The Bottom Line

With APPLIED’s adhesive expertise and technical service support, the co-packer:

- Eliminated packaging failures, such as pop-opens.

- Fully transitioned to Graco InvisiPac systems for greater operational efficiency.

- Strengthened operational resilience through preventative maintenance and technical audits.

The relationship has positioned the co-packer to pursue further cost savings and process improvements, including a move to an adhesive that is best for high-running/throughput equipment that has outstanding adhesion to a variety of substrates. Trust in APPLIED runs deep, as the customer confided in our team to conduct trials independently because of our proven ability to deliver results.

Due to the results that they have achieved, they now rely on APPLIED as a comprehensive supplier across product, equipment, and service needs.

This is the APPLIED difference. A relentless focus on customer success through adhesives, equipment, parts and service refined the co-packer’s manufacturing processes and drove measurable outcomes.