Built on Experience. Driven by Innovation. Focused on You.

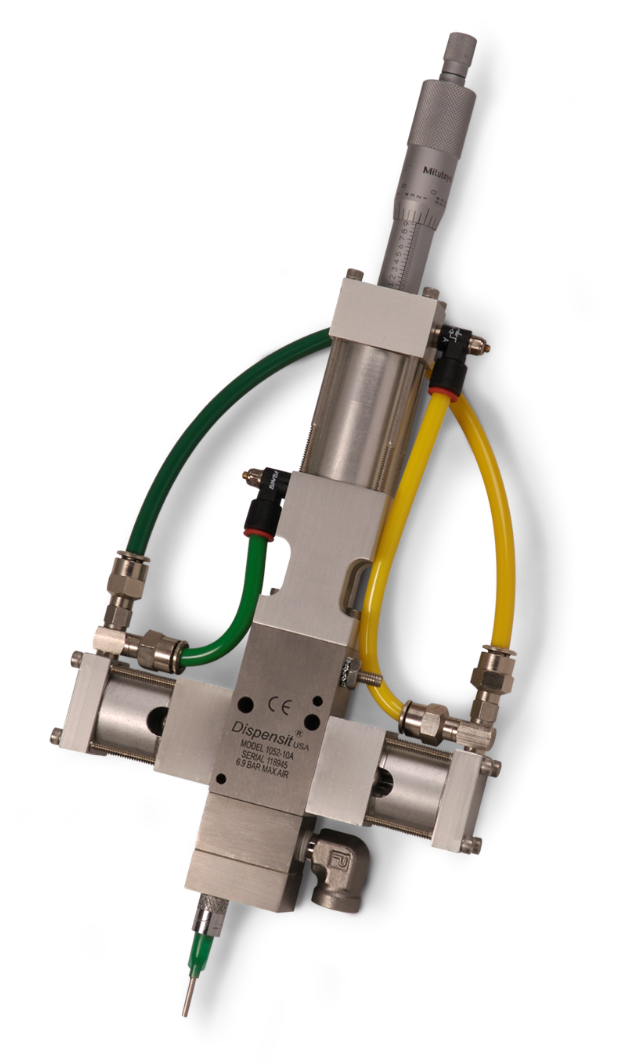

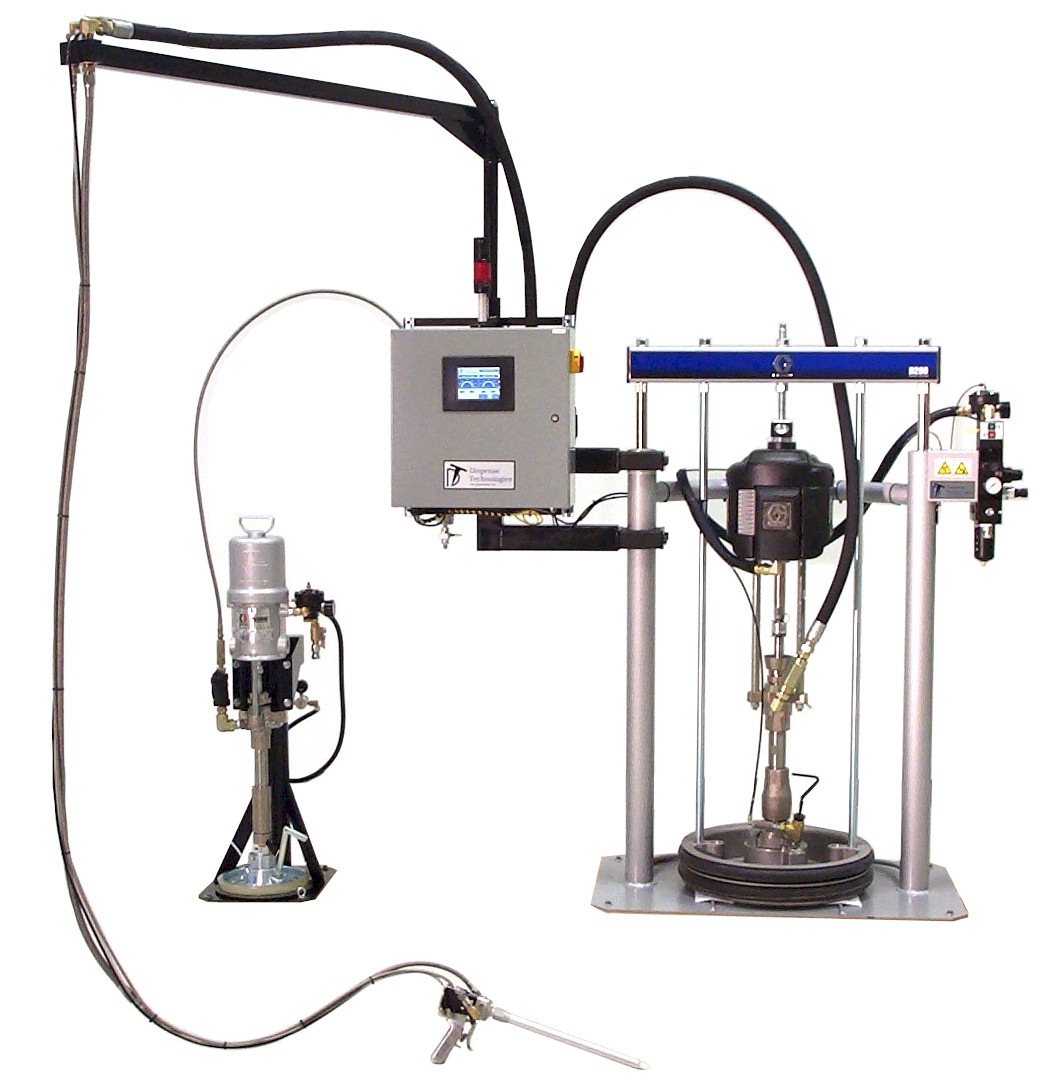

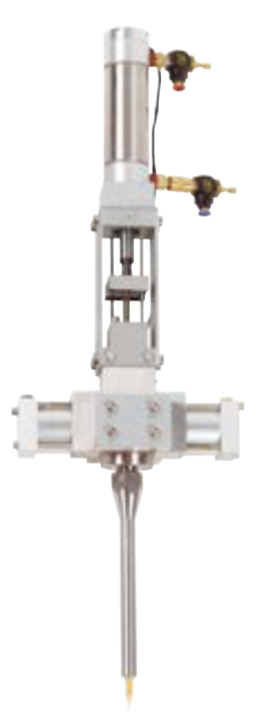

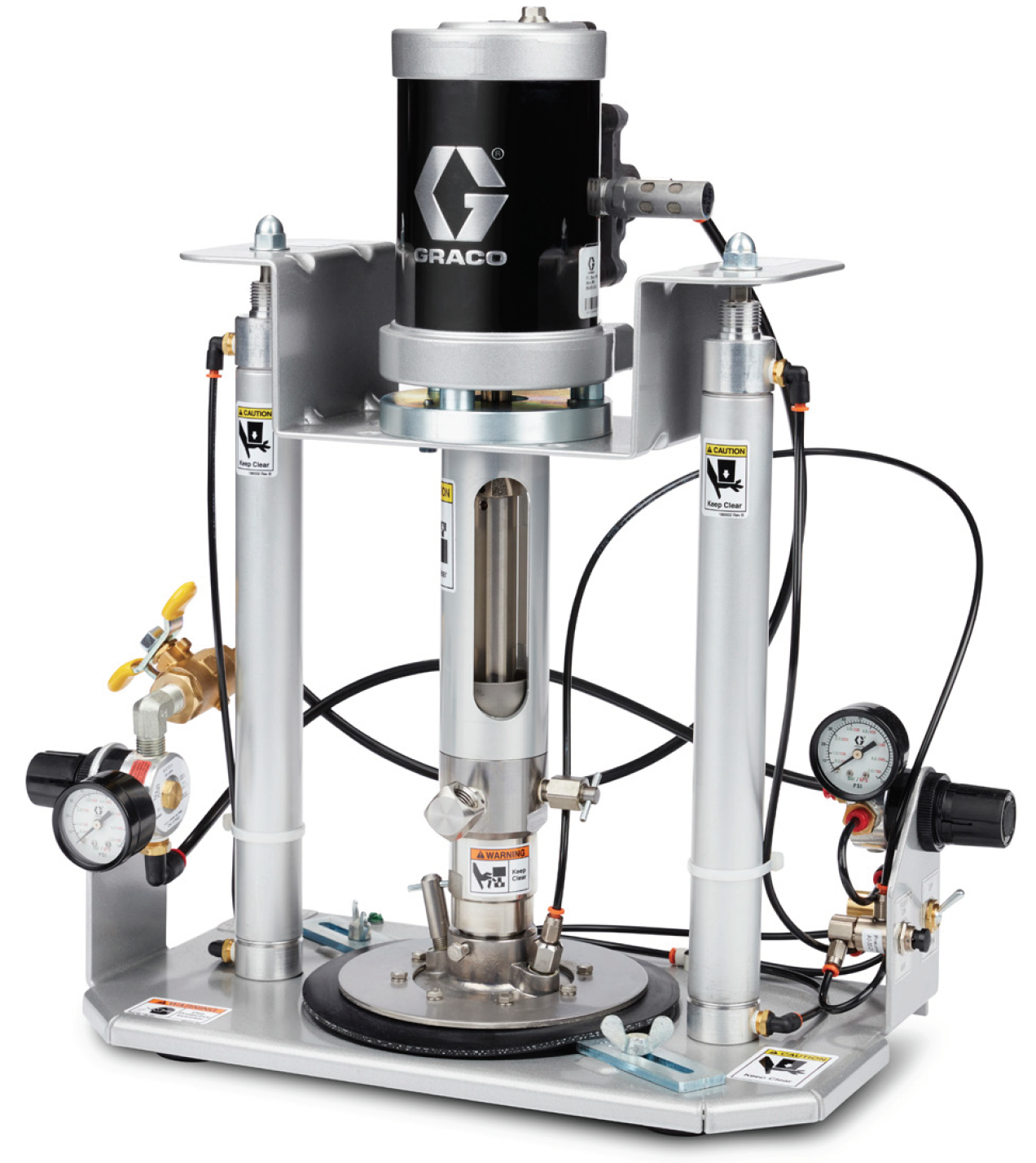

Dispense Technologies, now part of APPLIED Adhesives, has delivered high-performance fluid dispensing solutions that solve real-world challenges. As a trusted sealant and adhesive systems integration partner, we bring application expertise, engineering precision, and a relentless commitment to customer success across automotive, transportation, energy storage, and general assembly markets.